System KAN-therm PP Green is a complete installation system consisting of pipes and fittings of a thermoplastic polypropylene PP-R (type 3 / type 4) within a range of diameters 20-200 mm.

System elements are connected by muff-welding (thermal polyfusion) or electrofusons welding with the use of electric welders. The welding technology, thanks to uniform connections, guarantees an exceptional leak-tightness and mechanical strength of a system. The system is designed for internal water supply and cooling systems (hot and cold tap water) and for production process industrial systems.

From the System KAN-therm PP Green you can select six kinds of pipes differing in the wall thickness and the design (compound pipes):

All kinds of pipes are delivered in straight sections 4 m long.

To get more technical details click the type of a pipe you need.

System KAN-therm PP Green pipes (and connectors) are made of a PP-R/PP-RCT high-quality polypropylene.

In terms of the design there are two kinds of pipes: uniform (homogenous) and combined pipes (Stabi Al and Glass), characterized by their smaller thermal expansion. KAN-therm PP Stabi Al compound pipes consist of a uniform base pipe of the PP-R polypropylene surrounded by a coating of a perforated aluminium strip covered in addition by a protecting layer. For a better bonding of the aluminium layer with the polypropylene special binding glue layers are applied.

The design of KAN-therm PP Glass pipes is multi-layered. The glass fibre reinforced middle layer (40% of the pipe wall thickness) results in a high pipe strength and its small thermal expansion.

In diameter range above 110 mm, pipes are made of beta type random polypropylene copolymer (PP-RCT) which used to be marked as Type 4.

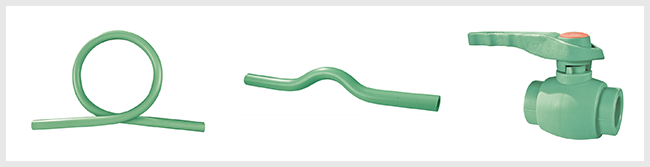

The KAN-therm PP System offers a full selection of muff-welded connectors (uniform, with metal threads, separable):

elbow

T-connection,

muff, reducer, plug,

connectors with male and female thread,

separable connectors,

other welded pieces.

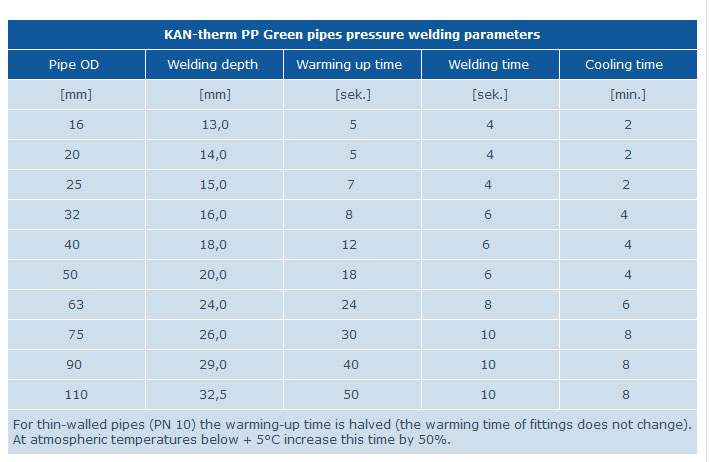

KAN-therm PP Green polypropylene elements are assembled by a polyfusion muff-welding process; in this method both surfaces to be joined, the external pipe surface and the internal surface of the fitting muff are heated up simultaneously at 260 0C. For heating (plasticization) an electric heater with a heating plate with exchangeable (for every diameter) covered in PTFE heating cover plates of is used. Depending on the diameter this heating takes from 5 to 90 seconds. After that time heated elements are taken out of heating plates and the pipe is immediately inserted into the fitting muff (no rotation movement allowed!) to a marked depth. Then the process of mutual diffusion and mixing of particles of both elements takes place.

With this welding process all the welding parameters must be maintained (warming up time, joining time and cooling time and the welding depth).

Connection technique - socket fusion welding (20-125 mm)

1. Cutting pipes with scissors.

2. Removing the aluminium foil with a foil remover.

3. Marking the welding depth.

4. Heating up the pipe and the fitting.

5. Joining the elements.

6. Holding together and cooling.

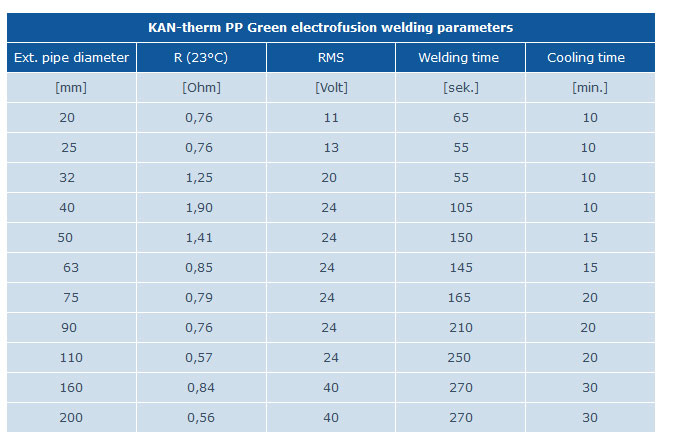

Another technique of assembly is electrofusion welding. A fitting with implanted metal coils is placed around two ends of pipes to be joined, and current is passed through the coils. Resistive heating of the coils melts small amounts of the pipe and fitting, and upon solidification, a connection is formed.

Connection technique - electrofusion welding (20-200 mm)

1. Pipe surface scraping.

2.Cleaning pipe surface with alcohol.

3. Insertion depth marking.

4. Insertion of pipe into the fi tting.

5. Programming of welding machine via laser reader (welding machine will adjust parameters automatically). 6. Welding process start - do not rotate or mechanically stress the elements througth all of welding and cooling process.

Due to the high quality and properties of the PP-material the System KAN-therm PP Green has many uses:

KAN-therm PP Green systems are irreplaceable, when replacing old and corroded water supply systems. They can be used also to overhaul heating installations.